Solder joint secure voltage relay DY-32/200 50-200V board front with seat JOSEF

Category:

electron/electrical/Liquid level controller

Model:

DY-32/200

Brand:

Shanghai Joseph

model:

DY-32/200

rated voltage:

two hundred and twenty

Place of Origin:

Shanghai

manufacturer:

Shanghai Joseph

Retail Price

165.00RMB

重量

kg

- Product Description

-

model DY-32/200

rated voltage two hundred and twenty

Place of Origin Shanghai

manufacturer Shanghai Joseph

Description :

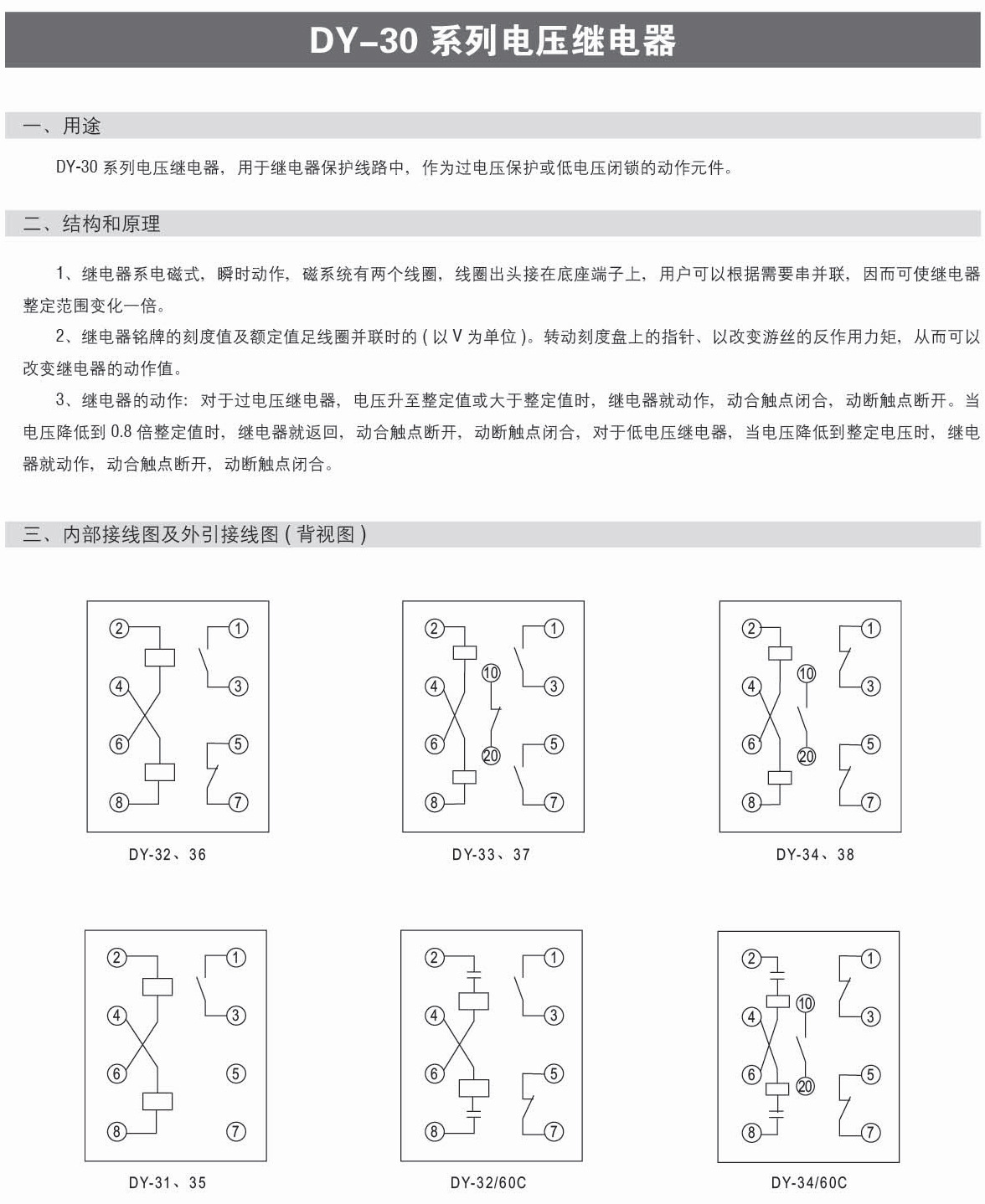

One purpose

DY series voltage relays are used in relay protection circuits as action components for overvoltage protection or low-voltage lockout.

II Technical Specifications

DY-32/60C and DY-34/60C specifications are long-term thermal stable (with built-in series capacitors) voltage relays.

● Relay scale limit error: not greater than 6%.

● Variation of action value: not greater than 6%.

The return coefficient of voltage relays DY-31, 32, 33, and 34 shall not be less than 0.8; DY-35、 The return coefficient of low voltage relays 36, 37, and 38 shall not exceed 1.25.

Action Time

For overvoltage relays

At 1.1 times the action value, the action time should not exceed 0.12s; at 2 times the action value, the action time should not exceed 0.04s.

For low-voltage relays

When the working voltage of the relay is 0.5 times the set voltage, the action time shall not exceed 0.15 seconds.

● Overvoltage capability: When the coils are connected in parallel, the voltage should be uniformly raised from zero to 1.05-2.2 times the set voltage at the minimum setting value. Within this range, the relay should not have any vibration that would cause the dynamic contact to not work. After this test, the relay should still meet the technical requirements.

● Overvoltage: When the setting value is increased by 1.75 times or higher, the dynamic contact of the relay should close without shaking.

When there are no external collisions or vibrations. When the working voltage at each setting position (excluding point *) of the overvoltage relay is 0.6 times the setting value, its dynamic breaking contact should reliably close the circuit.

When the working voltage of a low-voltage relay is 0.6 times the set voltage or lower, its dynamic breaking contact should close without shaking.

When there is no external collision or vibration, the working voltage at each setting position of the low-voltage relay should not be less than 1.5 times the setting voltage, and its dynamic contact should reliably close the circuit.

Under the action voltage and return voltage; The movable system of the relay should not be stuck in the middle position.

When the relative humidity of the surrounding air is not greater than 85%, the insulation resistance of the relay circuit to the shell (non-conductive metal part on the shell) should not be less than 300M Ω when measured with a 500V megohmmeter.

The insulation of the conductive part of the relay to the shell (non-conductive metal part on the shell) can withstand a test of 50Hz AC voltage 2kV for 1 minute.

● Contact breaking capacity: When the voltage is not greater than 250V and the current is not greater than 2A, the breaking power of the contact is 50W in a DC circuit with inductive load (time constant not greater than 5 × 10-3s) and 250VA in an AC circuit.

Power consumption: At the minimum setting value, the power consumed by the coil of the relay does not exceed 20VA.

When the temperature of the surrounding medium is+40 ℃, the relay can operate for a long time under the long-term allowable current and voltage shown in Table 2 and Table 3 without damage to insulation and other electrical components, and the temperature rise of the coil is not greater than 65 ℃.

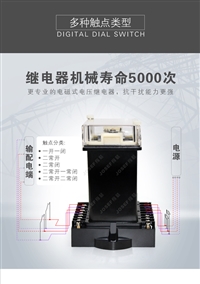

● Lifespan: The relay has an electrical lifespan of 500 times and a mechanical lifespan of 5000 times.

Usage and maintenance

Before using the relay, the housing needs to be removed, the machine needs to be pulled out, and there should be no damage caused during transportation: such as the moving plate touching the magnetic plate, the balance spring coils touching each other, friction on the moving plate shaft, etc. Therefore, set the pointer of the relay to the * setting point, manually rotate the movable system towards the magnetic plate direction, and then release it. The movable system should return to its original equilibrium position until the stop, and then make necessary adjustments and settings.

When readjusting the relay, it must be ensured.

The axial movement of the movable system is between 0.15 and 0.3mm.

The air gap between the rotor and the magnetic pole should ensure that the rotor and the magnetic plate do not collide under any specified working conditions of the relay.

Relays with dynamic contact points and dynamic contact points must not have bridge shaped contacts simultaneously make contact with dynamic contact points and dynamic contact points during operation.

When the pointer rotates from the * scale value to the * final scale value, the coils of the balance spring must not touch each other.

When the relay is activated, the bridge shaped contact should slide on the centerline of the static contact (tolerance ± 1mm), and the total air gap between the dynamic and static contacts should not be less than 2mm.

The distance between the static contact point and the limiting plate should not exceed 0.3mm.

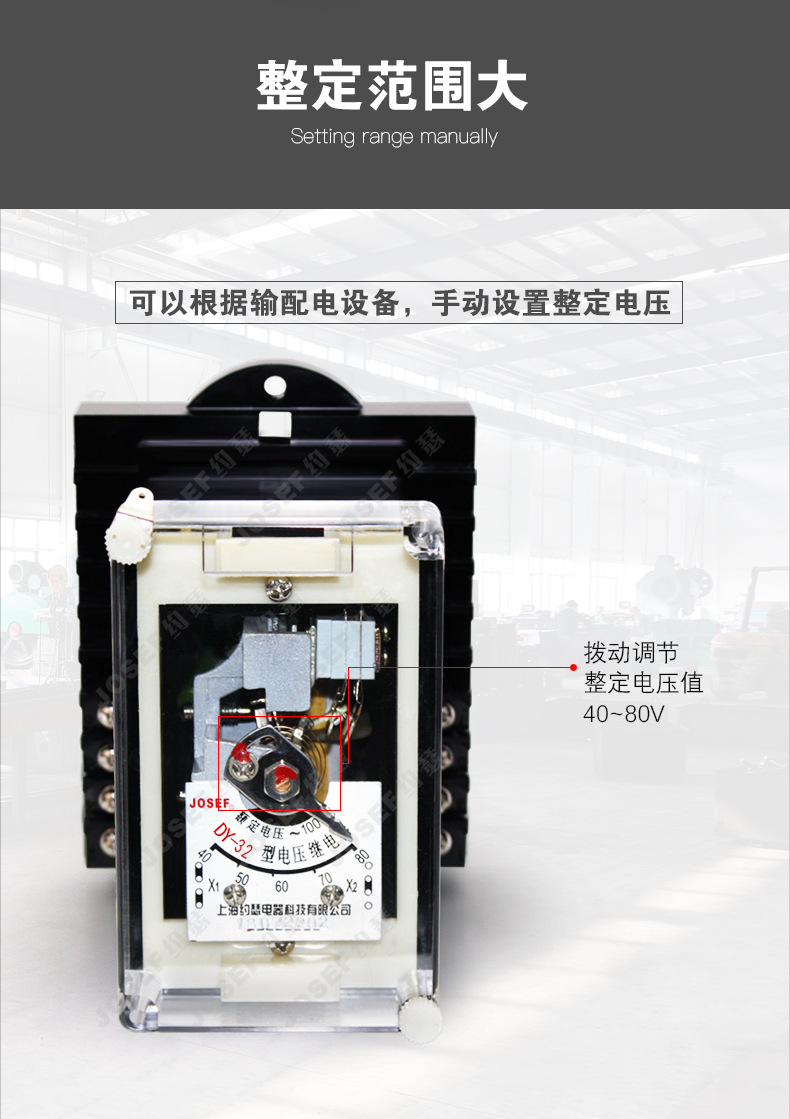

When adjusting the action value of the relay, the adjustment of the small setting value mainly changes the magnitude of the spring reaction force, while the adjustment of the large setting value mainly changes the air gap between the rotor and the magnetic plate.

Not suitable for lubricating relay shafts and bearings.

It is not allowed to clean the contacts with sandpaper or other rough materials. It is advisable to clean the contacts with a sharp blade or a clean fine grinding stone, and then wipe them clean with a clean, soft cloth to avoid touching the contacts with fingers.

Rear wiring of voltage relay DY-32/60C board

Voltage relay DY-36/160V board front with seat

Voltage relay DY-23C/60C with board front base

Voltage relay DY-29C setting value: 40-160V. Wiring in front of the fixed installation board inside the cabinet

Fixed installation of voltage relay DY-36 220VDC cabinet bottom plate

Fixed bottom plate of voltage relay DY-36/60C 220VDC cabinet

Voltage relay DY-29C/160 40~160V board front wiring

Voltage relay DY-48 set voltage AC160V, protruding board front wiring, 2 closed points and 1 open point

Front wiring socket of voltage relay DY-34/60C board

Voltage relay DY-28C set voltage AC160V, protruding board front wiring

Static passive undervoltage relay DY-38G (X) setting range 19-180V contact form: one normally open and two normally closed rail installation

Voltage relay DY-32 board with front seat

Voltage relay DY-33/60C 15-60V board rear wiring

Voltage relay DY-32/62C 60V fixed value 15V board front wiring

Voltage relay DY-37 voltage setting range 40-160V, pre board wiring

Voltage relay DY-54/32-132V

Voltage relay DY-38 setting voltage range: 12~48V Contact form: one normally open and two normally closed

Low voltage relay DY-28C/160

Voltage relay DY-34 100VAC 15~30V board rear wiring

Installation of voltage relay DY-54G 33~132V rail

Voltage relay DY-24C/60C

Voltage relay DY-36 80~320V with base

Installation method of low voltage relay DY-110: pre board wiring, working voltage: AC220V,

Voltage relay DY-34/60CG undervoltage type 15-100V with two normally closed contacts

Voltage relay DY-23C, D type, rated voltage 200V, 50~200V

Voltage relay DY-35, rated voltage 48V, 12-48V, including base

Voltage relay DY-32/200 50~200V board front with seat

Front wiring of voltage relay DY-31/200 board

Overvoltage relay DY-21C voltage setting range 50-200V board front with seat

Front wiring of voltage relay DY-34/60C-TH board

Voltage relay DY-24C/200 50-200V board front wiring

Front wiring of voltage relay DY-31 15~60 board

Key words:- voltage relay