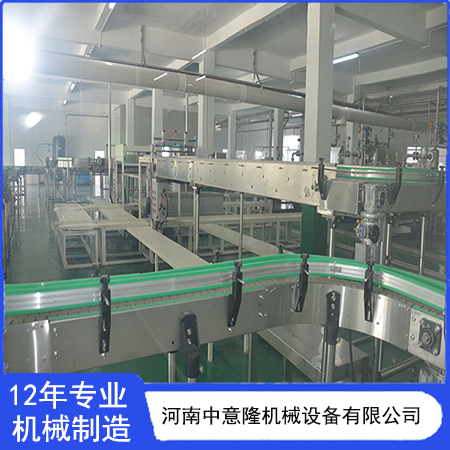

ZYL provides one-stop service for the equipment required by beverage factories, including cans and beverage processing equipment

Category:

mechanical equipment/Beverage processing machinery/Fruit and vegetable juice beverage production line

Model:

YLGYLSB-ZYL

Brand:

Zhongyi Long

brand:

Zhongyi Long

model:

YLGYLSB-ZYL

Item Number:

YLGYLSB-ZYL

type:

Can beverage equipment

Processing & Customization:

yes

Product Specifications:

eight thousand

Place of Origin:

Henan

Retail Price

223,000.00RMB

重量

kg

- Product Description

-

brand Zhongyi Long

model YLGYLSB-ZYL

Item Number YLGYLSB-ZYL

type Can beverage equipment

Processing & Customization yes

Product Specifications eight thousand

Place of Origin Henan

Description :

Zhongyilong provides one-stop service for the equipment required by the beverage factory, including cans and beverage processing equipment

Can filling machine

The Henan Zhongyilong can filling machine adopts pneumatic control with no contact with the can body for automatic capping, and adopts equal liquid level filling technology. Its production capacity is variable frequency speed regulation, and more than 95% of the appearance material is stainless steel. To improve the vacuum degree inside the can, a steam injection device can be configured according to customer requirements. To ensure maximum technical support for customers, a remote monitoring system can be equipped.

One Several advantages of Henan Zhongyilong can beverage filling production line:

1. The filling machine is designed and manufactured by our company using German technology and the principle of atmospheric pressure filling, to fill liquids into washed cans.

2. The filling adopts the principle of gravity filling.

3. The filling valve adopts a mechanical valve, which has fast filling speed and high liquid level accuracy.

4. It has a complete CIP cleaning function.

5. The combination of a filling valve with a guiding device and a bottle bottom lifting device ensures accurate sealing between the bottle mouth and the filling valve, reducing the phenomenon of material leakage from the tank mouth.

6. Depending on the height of the tank, manual lifting can be achieved to meet the filling requirements.

7. Adopting gear transmission has high efficiency, low noise, long service life, easy maintenance, and sufficient lubrication. The main motor speed of the machine is controlled by a frequency converter, and this machine adopts stepless frequency conversion speed regulation.

8. The bottle guide system has a simple structure and can be quickly and conveniently changed according to the tank type. The whole machine adopts a bottom support structure for transportation.

9. The whole machine is automatically controlled by PLC, and faults such as bottle blockage and missing caps are displayed online.

10. It has safety protection functions such as no valve opening without a can, no cover, and shutdown without a cover.

11. The material in the filling cylinder is automatically controlled, and the liquid level height is detected by a liquid level sensor to ensure stable liquid level.

The key components and electrical components of this machine are imported products.

II Sealing part of can filling machine: can filling machine

a. The sealing part seals the lid onto the can that has already been filled with the product and sends it to the subsequent process through the conveyor chain.

b. The sealing roller adopts high hardness alloy quenching (HRC>62), and the sealing curve adopts optical curve grinding precision machining to ensure the quality of sealing and the normal operation of the machine.

c. This machine has a lid control system with a can under lid and no lid without a can, ensuring normal operation of the machine and reducing the rate of lid damage.

d. Manually place the aluminum cover in the chute and use the cover gravity and thruster to lower it. The chute is equipped with a detection switch for stopping the machine when the cover is missing.

e. According to different heights of tank types, the capping machine can be manually raised and lowered to meet the requirements.

III Technical parameters of Henan Zhongyilong can filling machine:

Rated output: 8000BPH (335ml can)

Tank height: 80-135mm

Can diameter: ф 45~ф 70 mm

Applicable can type: Easy pull can (200, 202, 206, 209 need to be changed)

Applicable cover type: Standard aluminum cover

Filling method: gravity filling

Number of filling heads: 18

Filling temperature: 0-92 ℃

Filling valve flow rate:>150ml/s

Number of sealing heads: 4

Motor power: 3.75KW

Compressed air consumption: 0.05m3/min (at 0.6MPa)

Dimensions: 3150 × 1730 × 2700mm

Total weight of the machine: 3500Kg

Key words:

Key words:- Equipment required for beverage factories

More Products