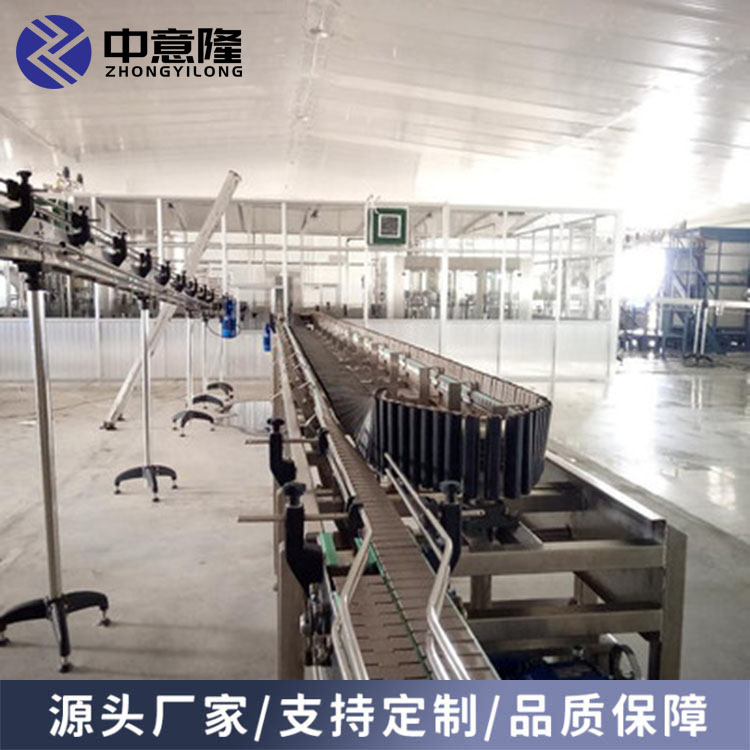

280ml Walnut Dew Protein Beverage Processing Equipment, Can Packaging, Complete Walnut Dew Production Line Manufacturer

Category:

mechanical equipment/Beverage processing machinery/Fruit and vegetable juice beverage production line

Model:

ZYL-HTLJGSB

Brand:

Zhongyi Long

brand:

Zhongyi Long

model:

ZYL-HTLJGSB

Item Number:

ZYL-HTLJGSB

type:

Walnut Dew Processing Equipment

Processing & Customization:

yes

Product Specifications:

280ml

Place of Origin:

Henan

Retail Price

260,000.00RMB

重量

kg

- Product Description

-

brand Zhongyi Long

model ZYL-HTLJGSB

Item Number ZYL-HTLJGSB

type Walnut Dew Processing Equipment

Processing & Customization yes

Product Specifications 280ml

Place of Origin Henan

Description :

280ml Walnut Dew Protein Beverage Processing Equipment, Easy Can Packaging, Complete Walnut Dew Production Line

Walnut milk beverage production lineThe processing technology

Production process flow

Walnut kernels → selection → rinsing → soaking → peeling → color protection → grinding → filtering → blending → pre homogenization → vacuum deodorization → homogenization → filling → sterilization → cooling → inspection → finished product

2. Key points of operation

1. Selection and rinsing: Select fresh walnut kernels that are free from insect infestation, mold, and oil spills, and rinse them with clean water to remove foreign objects such as mud, sand, and residual shells.

2. Soaking: Soak the walnut kernels in clean water to make them absorb water and expand, soften the tissue, and facilitate peeling, grinding, and extraction of nutrients. When soaking, the ratio of walnut kernels to water is about 1:2, and the soaking time is 4-5 hours, because later color protection treatment requires soaking for 3-4 hours.

3. Peeling: Boil walnut kernels in a 3% NaOH solution for 3-5 minutes, then rinse with high-pressure water to remove the seed coat.

4. Color protection: Use 0 5% NaCl and 0 Soak the peeled walnut kernels in a 02% NaSO3 mixed solution for 3-4 hours, perform color protection bleaching treatment, and then rinse twice with clean water.

5. Grinding: Using a grinding wheel grinder, the method of hot water grinding at 85 ℃ or above is adopted to passivate lipoxygenase. The ratio of water to walnut kernels is 7:1.

6. Filtration: Use a 200 mesh centrifuge to separate the pulp and residue. To improve protein yield, the residue can be soaked and extracted with hot water, and the slurry can be used as water for the next grinding.

7. Preparation: Dissolve and filter white sugar, emulsifier, thickener, etc., mix them with walnut slurry according to the formula ratio, and stir evenly. Soft water with a hardness of less than 4 degrees should be used for mixing water to prevent protein aggregation and precipitation caused by metal ions.

8. Pre homogenization: Use colloid grinding once, which is called pre homogenization, to thoroughly mix and refine the material liquid for degassing, deodorization, and high-pressure homogenization.

9. Vacuum deodorization: The feed liquid is deodorized in a vacuum deodorization tank under a vacuum degree of 20-30 kPa. It also plays a role in degassing. And quickly cool the liquid to below 85 ℃.

Process flow and operation essentials of juice beverage production line (1) Raw material selection: Soft fruits with high maturity should be selected as raw materials for production, and fermented, spoiled, and unripe fruits should be removed. (2) Cleaning: Washing the raw materials before juicing is an important measure to reduce pollution, especially when juicing with skin. Therefore, it is necessary to wash the sediment and impurities on the fruit peel with flowing water. Rinse with solution if necessary, then rinse with clean water. (3) Beating: The concentrated juice production line uses a beater to mash and peel the fruit pulp, and the pulp is wrapped in cloth to extract the juice, with a juice yield of over 70%. Alternatively, the cleaned fruit can be poured into a press for juice extraction, and then filtered through a scraper filter to remove the skin, seeds, and some coarse fibers. (4) Preparation: The roughly filtered juice is diluted with water to a refractive index of 4%. Then mix 90 kilograms of juice with 10 kilograms of white sugar, continuously stirring until the sugar dissolves. (5) Filtration: The prepared juice is filtered and separated by a centrifugal filter to remove residual skin, seeds, some fibers, minced flesh, and impurities. (6) Homogenization: The filtered juice is homogenized by a homogenizer, which can further break down the small fruit pulp and maintain the uniform turbidity of the juice. The homogenizer pressure is 10-12 megapascals. (7) Sterilization and cooling: High temperature sterilization and other methods are used to sterilize concentrated fruit juice, with a sterilization formula of 5 '-10'/100 ℃, and then quickly cooled to below 40 ℃. (8) Filling and sealing: Heat the juice, fill it at a temperature not lower than 80 ℃, and quickly seal it

Henan Zhongyilong Machinery Equipment Co., Ltd. is capable of producing a complete set of protein beverage production equipment, blueberry juice beverage production lines, blueberry juice beverage equipment, fruit juice beverage production lines, purified water production lines, sea buckthorn juice production lines, peach beverage production lines, corn juice production lines, yam juice production lines, salt gas water production lines, carbonated beverage production lines, etc., with the production of supporting parts and equipment for the production lines as by-products, in a large-scale group production mode. The sea embraces all rivers, and tolerance is great; Sincerity in the world, sowing the future. Blueberry juice beverage production line process: cleaning → conveying → juicing → filtering → enzyme inactivation → pasteurization → high-temperature instantaneous → aseptic filling → bottle sterilization → spray cooling → air drying → coding → packing → finished product. The device is multifunctional and versatile, suitable for filling and sealing various liquids and bottle types. This also provides space for the production enterprises of juice beverage production lines, so that we can occupy a place in the market. Zhongyilong Machinery produces a fully automatic washing, filling, and sealing machine, which is fully suitable for the requirements of juice beverage production and is highly welcomed by beverage manufacturers.

Key words:

Key words:- Walnut protein beverage processing equipment

More Products