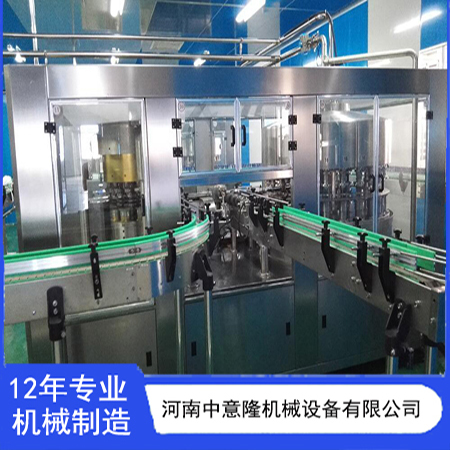

Zhongyilong small beer production line equipment can beer complete set of equipment customized according to needs

Category:

mechanical equipment/Beverage processing machinery/Fruit and vegetable juice beverage production line

Model:

ZYL-PJLZSCX038

Brand:

Zhongyi Long

brand:

Zhongyi Long

model:

ZYL-PJLZSCX038

Item Number:

A038

type:

Beer production and processing

Processing & Customization:

yes

Product Specifications:

2000-7000 bottles/hour

Place of Origin:

Henan

Retail Price

220,000.00RMB

重量

kg

- Product Description

-

brand Zhongyi Long

model ZYL-PJLZSCX038

Item Number A038

type Beer production and processing

Processing & Customization yes

Product Specifications 2000-7000 bottles/hour

Place of Origin Henan

Description :

Zhongyilong small beer production line equipment can beer complete set of equipment customized according to needs

Beer production can be roughly divided into three main processes: malt production, beer brewing, and beer filling.

1. Malt production:

Mix the malt/grains that are about to be crushed with water in a gelatinization pot. In the gelatinization pot, malt and water are heated and boiled, and then the malt extract is sent to a filtering container called a separation tower. Before being pumped into the boiling pot, the malt extract needs to be filtered to remove the malt husk and added with hops and sugar.

2. Beer brewing:

Saccharification: Mix the crushed malt and starch excipients with warm water in a gelatinization pot and a saccharification pot respectively, and adjust the temperature. Mix the fully liquefied mash from the gelatinization pot into the saccharification pot and maintain it at a temperature suitable for saccharification (62-70 ℃) to produce wheat mash.

Fermentation: The vast majority of yeast settles at the bottom of the tank. After removing yeast, the product "tender beer" is pumped into the post fermentation tank. Here, the remaining yeast and insoluble proteins further precipitate, gradually maturing the style of the beer. The maturation time varies with different beer varieties, generally ranging from 7 to 21 days.

3. Beer filling:

Packaging often comes in several forms: bottled, canned, and barreled. In addition, the differences in bottle shape and capacity, labels, neck covers, and bottle caps, as well as the diversity of outer packaging, constitute a dazzling array of beer products in the market.

Key words:

Key words:- Small beer production line equipment

More Products