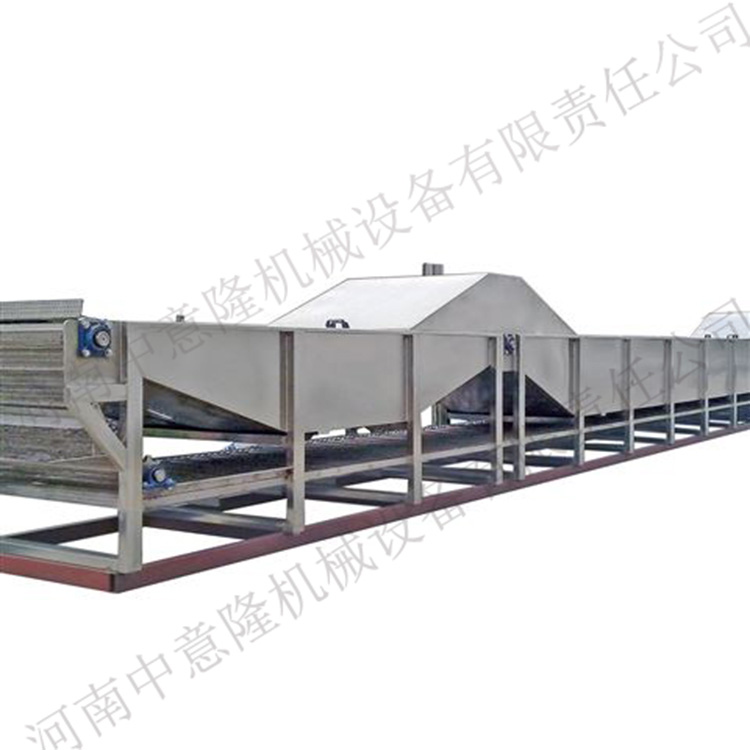

ZYL complete set of Babao Congee production and processing equipment easy open can Babao Congee production line

Category:

agriculture/agricultural machinery/Grain processing equipment

Model:

ZYL-BBZSCX01

Brand:

Zhongyi Long

Retail Price

255,000.00RMB

重量

kg

- Product Description

-

Description :

Zhongyilong Machinery produces single machine equipment including:

1. Pre processing equipment:Including water treatment systems, beverage mixing tanks, fruit wine fermentation tanks, enzyme fermentation tanks, acetic acid fermentation tanks, biological fermentation tanks, maturation tanks, aging tanks, sterile tanks, fruit and vegetable cleaning machines, fruit and vegetable crushers, fruit beaters, screw juicers, storage tanks, refrigeration tanks, chelating tanks, UHT plate sterilizers, UHT tube sterilizers, UHT ultra-high temperature instantaneous sterilizers, CIP cleaning machines and other standalone machines.

2. Composition of PET bottle production equipment:A complete set of filling and packaging production lines, including automatic bottle blowing machine, wind conveyor line, cap sterilization machine, cap cleaning machine, three in one bottle flushing, filling and capping machine, bottle pouring sterilization machine, cold bottle machine, blow drying machine, labeling machine, coding machine, palletizing machine, winding machine, solid bottle conveying system, box conveying system, electrical control system, etc. Optional equipment: automatic bottle sorting machine or manual bottle sorting system, fully/semi automatic bottle washing machine, fully automatic bottle unloading machine, bottle warehouse, labeling machine, carton packaging machine, etc. Production capacity: Shangyun Company has formed a complete series of product lines, with a supply capacity ranging from 2000 bottles/hour to 24000 bottles/hour (calculated based on 500ml PET bottles).

3. Composition of can loading equipment:A complete set of filling and packaging production lines including fully automatic can unloading machine, can flushing machine, filling and sealing machine, cold can machine, storage tank platform, liquid level detection machine, shrink film packaging machine, solid tank transportation system, electrical control system, etc. Optional equipment: cardboard packaging machine, etc. Production capacity: Our company has formed a complete series of product lines, with a supply capacity ranging from 1000 cans/hour to 24000 cans/hour (calculated based on 355ml cans)

4. Composition of glass bottle equipment:A complete set of filling and packaging production lines including bottle washing machine, bottle preheating machine, cap sterilization machine, filling and capping machine, bottle pouring sterilization machine, cold bottle machine, labeling machine, packing machine, palletizing machine, winding machine, solid bottle conveying system, box conveying system, electrical control system, etc. Optional equipment: If it is a new bottle, a fully automatic bottle unloading and stacking machine can be selected. Production capacity: Our company has formed a complete series of product lines, with a supply capacity ranging from 2000 bottles/hour to 24000 bottles/hour (calculated based on 250ml glass bottles).

5. Packaging equipment for the later stage of the production line:A series of products including unboxing machines, packing machines, wrapping machines, sealing machines, palletizing machines, etc.

Process characteristics of complete set of Babao Congee production and processing equipment

The processing of the whole set of Babao Congee production line provided by Zhongyilong Machinery meets the food production requirements, and the parts in contact with materials are made of stainless steel ICR18N19Ti. We can provide on-site installation and technical training, and implement a turnkey project.

1. The function of water treatment: After water treatment, it can improve the taste and shelf life of the product.

2. Equipped with a high shearing hot and cold cylinder, it can speed up the batching speed and improve the viscosity of Babao Congee.

3. Fully automatic filling production line: automatic bowl filling, automatic rice dropping, automatic printing of production date, automatic sealing and cutting

4. The sterilization adopts a rotary sterilization machine, which can make the materials in the bowl more evenly cooked, sterilize more thoroughly, and extend the shelf life.

Babao Congee can be filled with raw materials better than cooked ones. There are two reasons for this:

The Babao Congee filled with raw materials is sterilized after packaging. Sterilization is also a process of cooking. When the product is cooked in a can, its oxidation is basically blocked, and the aroma will not be sent out, so its color is well maintained, flavor is strong, and nutrition loss is small.

Key words:

Key words:- Complete set of Babao Congee production and processing equipment

More Products