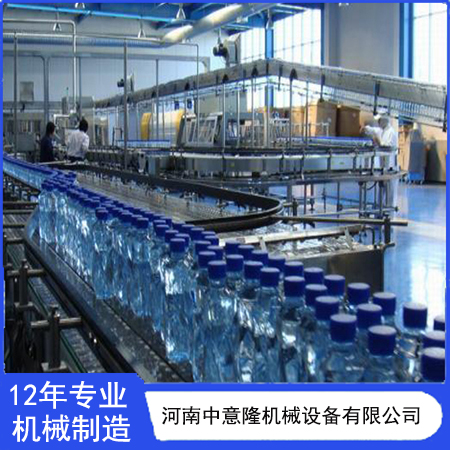

Supply small bottle water production line, mineral water production line equipment, mineral water processing equipment

Category:

mechanical equipment/Beverage processing machinery/Bottled water production line

Model:

ZYL-KQSSCX002

Brand:

Zhongyi Long

Retail Price

186,000.00RMB

重量

kg

- Product Description

-

Description :

Introduction to Mineral Water Production Line Equipment

1. Production process flow of mineral water production line equipment

Raw water tank → Raw water pump → Fine sand filter → Activated carbon adsorber → Precision filter → Ultrafiltration device → Ultraviolet sterilizer → Pure water tank → Filling equipment. The ultrafiltration (UF) device is a key equipment in mineral water production equipment, and the right tube ultrafiltration device and roll ultrafiltration device are widely used in mineral water production equipment now. The mineral water production line equipment adopts hollow fiber ultrafiltration membranes and their devices produced from polysulfone, polypropylene, and other polymer materials. The product structure is compact, the design is reasonable, and there are water production, backwashing, and chemical cleaning processes. The operation is simple and convenient, the operation is safe and reliable, the water production rate is high, the pollution is resistant, and the attenuation is small. It can effectively intercept suspended solids, particles, colloids, bacteria, heat sources, and large molecular organic matter in water. Similar to reverse osmosis technology, it is a membrane separation technology driven by pressure. In the spectrum of the separation range from reverse osmosis to electric microfiltration, it is located between nanofiltration (NF) and microfiltration (MF), with a cut-off molecular weight range of 50-500000 daltons and an approximate membrane pore size of 50-1000A.

The mineral water production line equipment is a solution separation system based on the mechanical screening principle, powered by the pressure difference on both sides of the membrane. The operating pressure is usually 0.2MPa-0.6MPa, and the separation pore size is 1nm-0.1 μ m. It can be widely used for material separation, concentration, and purification. The ultrafiltration process has no phase transformation and operates at room temperature, making it particularly suitable for the separation of thermosensitive substances. It also has good temperature resistance, acid and alkali resistance, and oxidation resistance, and can be used continuously for a long time under conditions below 60 ℃ and pH 2-11.

Ultrafiltration (UF) devices are key equipment in mineral water production lines, and are now widely used in right tube and roll ultrafiltration devices in mineral water production line equipment.

The tubular ultrafiltration device has good flow conditions, is not easy to block, and is easy to clean. It is suitable for applications such as electrophoretic paint recovery, juice concentration, silica sol production, oil-water separation, etc.

2. Characteristics of Mineral Water Production Line Equipment

1) The membrane area is large.

2) The structure of the device is compact.

3) Easy installation and maintenance.

4) Less land occupation.

5) Compared to other ultrafiltration devices, it has the advantage of low energy consumption, but requires higher pre-treatment than tubular ultrafiltration devices.

The mineral water production line consists of the following three parts:

① Water treatment system: quartz sand, activated carbon, sodium ions, ultrafiltration, hollow fibers, ultraviolet sterilization.

② Bottle blowing and filling system: bottle blowing machine, bottle sorting machine, capping machine, filling machine, lamp inspection equipment

③ Mineral water packaging system: inkjet printer, blow dryer, labeling machine, film wrapping machine, palletizer.

Calculated based on 500ml bottles, a linear mineral water production line is generally used for production below 2000 bottles per hour, while a mineral water three in one filling machine is used for production above 2000 bottles per hour.

Multi functional bottle blowing machine: The entire machine is operated through a touch screen to achieve human-machine dialogue. Specially designed secondary blowing system ensures stable quality of bottle molding. The heater adopts a four stage infrared temperature control and a digital automatic voltage stabilization temperature control system, which can set the corresponding heating temperature according to different bottle preforms of the user. It has the characteristics of reasonable structure, small footprint, low power and gas consumption, and strong stability.

Bottle sorting machine: PLC control combined with variable frequency speed regulation ensures synchronous operation of the entire production line. Adopting a three time recommendation bottle dispensing mechanism to improve bottle dispensing efficiency. The unique design of the bottle dropping component adapts to bottles of different lengths. The bottle extraction wheel is equipped with a bottle jam detector. The umbrella shaped tower is equipped with detectors that control the storage volume of bottles in the main engine compartment by starting and stopping the hoist. The reverse bottle is connected to the bottle mouth of the air duct during the bottle extraction wheel to prevent the bottle from getting stuck halfway. The bottle dispensing area is controlled by a synchronous belt and star wheel to ensure stable dispensing without bottle tipping or squeezing. The whole machine adopts a centralized lubrication system for fixed-point, timed, and quantitative lubrication.

Water treatment equipment: Using original American nanofiltration membranes (such as RO membranes for mineral water), the water source can be groundwater or tap water, ensuring that the effluent quality meets national mineral water standards. This system includes (raw water tank, water treatment, sterilization equipment, pure water tank, etc.)

Empty bottle air conveying system: The air duct conveying line is designed for conveying empty PET bottles of various shapes and sizes. Modular design, easy and fast installation of air ducts and layout of workshop production lines. Different conveying methods can be designed for bottles of different specifications. Control the conveying speed by adjusting the wind pressure and speed.

Bottle cap cleaning machine: Rinsing bottle caps with liquid medicine can solve the problem of dust generated during transportation and storage of bottle caps.

Three in one mineral water filling machine: The mineral water production line integrates flushing, filling, and capping, using star wheel rotation technology. The air duct is directly connected to the bottle feeding wheel, and the bottle transmission adopts full process bottleneck technology. Changing the bottle shape does not require adjusting the equipment height. Based on 500ml PET bottles, the output of the bottled water filling machine can reach 2000 to 36000 bottles per hour. All parts are fully automated for processes such as bottle washing, filling, and sealing. The three in one unit completes the three processes of bottle washing, filling, and sealing in one go, with minimal bottle wear and accurate and stable transmission.

Bottle body water blower: A high-pressure fan blows air to blow away residual water droplets from the bottle body by spraying high-speed air from the narrow slit. The slit is arranged in an inclined manner, and all sides of the bottle can be blown by high-speed winds. Modular design of labeling equipment for static cutting. Adapt to various bottle shapes and bodies.

Laser coding machine: safe, non-toxic, no consumable materials, * type marking. Energy saving and energy-saving.

Membrane packaging machine: adopting imported PLC automatic control, human-machine interface, accurate tracking, secondary packaging entering state, eliminating bottle shortage and pouring, and flexible adjustment. Adjustable hot air circulation structure, suitable for various heat shrink films (including color printing), with fast and easy film replacement.

Packing machine: Bottles and cans are separated and stacked separately, lifted by a vacuum gripper, and then lowered into open cardboard boxes; The boxing machine can be equipped with an unboxing machine and a sealing machine before and after.

Key words:

Key words:- Small bottle water production line

More Products